The fastest-growing industrial technique is additive manufacturing (AM), which offers creative, cost effective and environmentally friendly solutions. Industry reports predict that during the next five years, additive manufacturing will expand at a rate of 20% to 22% each year.

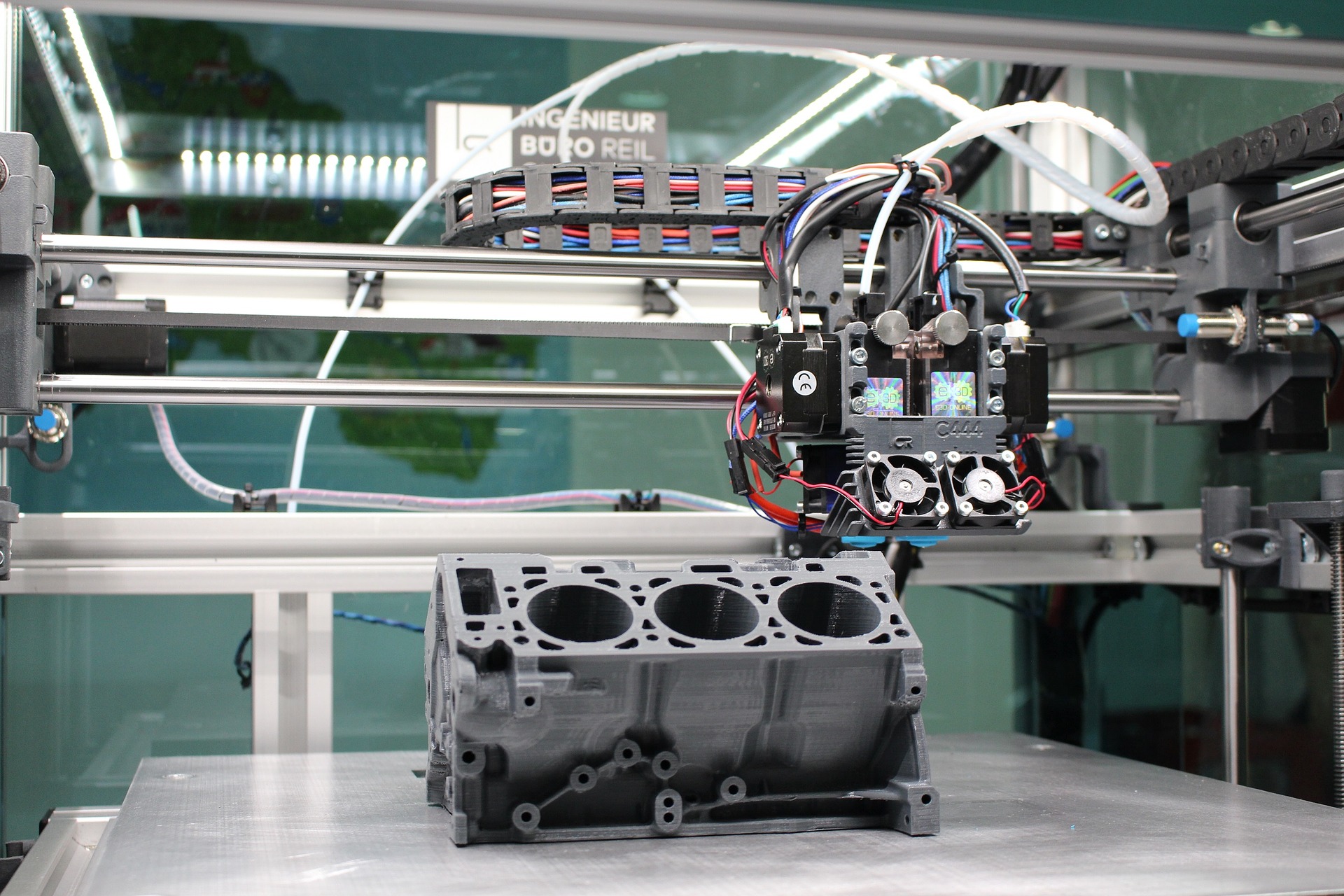

Manufacturers may accelerate the release of (better) products onto the market and prevent supply chain delays with the aid of additive manufacturing. AM technologies have been used for prototyping mostly in the aerospace, defense, dental, and automotive industries over the years. Nonetheless, the effectiveness of 3D printing automotive and aviation parts and components has just been demonstrated.

In the years that followed, there was a global industry downturn, which presented an opportunity for 3D printing to rise to the occasion in the wake of the COVID pandemic.

In this blog, a comprehensive review on the utilization, trends and predictions of AM technologies in Various industries is presented.

Changes in Supply Chain

It's important to note how 3D printing has been able to assist with supply chain disruptions throughout the world in the last few years. The COVID-19 pandemic served as an example of the practical use of additive manufacturing technology, since it led to the widespread availability of 3D printed face masks and shields. For instance, Stratasys was able to manufacture over 100,000 face shields for hospitals, and medical professionals by collaborating with many partners.

A global network of businesses undertook similar endeavors as the manufacturing of respirator parts, hands-free door openers, temporary emergency isolation areas, test swabs, and mask adjusters became essential. More than ever in the history of 3D printing, community creativity and inventiveness have been fostered by movements like the "innovate2ventilate" project.

Additive manufacturing still has a significant impact on supply chain management today. Thanks to technology, extra physical spare components are no longer needed because they can be digitally saved. In addition, more products may be generated fast if needed, as demonstrated during the epidemic.

As a result, businesses can control their products more effectively from the beginning, cutting expenses and waste.

With new materials for 3D printing hitting the market, a wider variety of printers, and an expanding array of additive manufacturing techniques, it makes sense for many businesses to outsource certain 3D printing tasks to businesses with specialized knowledge.

Simplified supply chains are quite sensible for businesses that require small batch production for quick prototyping, replacement parts, tooling, jigs, and fixtures, according to Market verse.

However, other sectors of the economy and businesses aim to take the exact opposite approach and internalize 3D printing. For example, 3D printers are becoming more common in dental offices, hospitals, and most importantly, classrooms.

New Materials

In the forefront of 3D printing by 2024 will be new materials (with new mechanical properties and new possibilities). Pay close attention to the bio-printing and additive manufacturing areas for metal.

Additionally, new businesses are expected to adopt additive manufacturing, which will lead to advancements in the kinds of materials that work well for those industries. A manufacturing renaissance centered around 3D printing is anticipated in a number of industries, including flexible electronics, energy production, and lifestyle/well-being items.

Increased 3D Printing Education

More industry professionals are in need and interested in learning about additive manufacturing as it is embraced by more industries and businesses. there is no doubt that, more people will use 3D printing training and upskilling in 2024, especially in the form of remote, online, and virtual courses.

There will probably be higher-level courses available that concentrate on in-depth understanding of additive manufacturing in particular sectors and important subfields within those industries.

Better Sustainability

Reducing environmental effect is (or should be) at the top of the agenda for all industries and manufacturers in light of the awareness of climate change and numerous worldwide government initiatives. Even though opinions differ throughout the world, I am confident that in 2024, efforts to advance the 3D printing industry will continue to pick up steam thanks to new discoveries and a surge of creative ideas from industry participants.

Additive manufacturing will be investigated by more industries to:

Utilize less energy.

Cut down on waste and the number of materials needed (many of which are recyclable and lightweight).

Not to mention the ability to print full assemblies at once rather than several separate parts.

Despite being more "eco-centric" by nature than conventional production techniques, the 3D printing sector is nonetheless under pressure to improve where it can. For instance, unless the project has some sort of sustainable component, such plans for product recycling or sustainable materials, polymer 3D printing might not be taken into consideration as the preferred approach. Additionally, there is a growing focus on optimizing workflows.

Customers are also thinking about transparency in sustainability. People are becoming more and more demanding that goods, packaging, production processes, and services have as little of an impact on the environment as possible (and that they can demonstrate this). Therefore, businesses using additive manufacturing and those dependent on the technology will need to take proven sustainability into account.

Greater customization & automation

With regard to goods and services, consumers are requesting greater personalization, and additive manufacturing makes it possible for this idea to flourish. We will undoubtedly witness more of this in the upcoming year. Furthermore, in 2024, additive manufacturing will probably be able to automate the production of vast quantities of product components.

Automation, which is mostly made possible by AI, allows businesses to:

Reduce expenses

Streamline processes

Improve the safety and health procedures.

Make sure that the criteria for product quality are controlled and maintained.

When you combine these developments, you'll see more products made using 3D printing that are of greater quality because of automated order administration, the printing process itself, material management, and post processing—not to mention the extra benefit of customization before purchase.

Trends and Future of AM

In my opinion, AM's capacity to quicken innovation will be crucial for consumer goods as well. AM used to be thought of solely as a tool for prototyping, which sped up the process of developing new products. I predict that a lot of consumer goods businesses will keep incorporating additive manufacturing (AM) into production workflows for a variety of applications as 2025 approaches, particularly in the automobile sector. Customers are still looking for the newest gadgets to help them manage their personal life and interact more easily. In addition to enabling quicker product development timeframes, AM's capacity to accelerate innovation will allow businesses to design products that push the boundaries of what is possible to deliver, giving customers access to capabilities they had never dreamed possible.

In some cases, additive manufacturing may not be able to completely replace traditional manufacturing, but it does provide advantages including quicker prototyping, less expensive replacement components, and the ability to produce customized tools.

The various global issues at hand have an impact on additive manufacturing, just like they do on all other industries.

Key trends to watch in the additive manufacturing space include supply chain interaction, recently developed materials, ongoing upskilling, sustainability opportunities, enhanced customization, and increased automation.

.jpg.webp)

.jpg)

.png)

Leave your thought here

Your comments are valuable for us. Required fields are marked *